BRUCKS

BRUKS is one of the world leaders in the design and manufacture of equipment for industrial handling of bulk materials. The guaranteed reliability of BRUKS equipment is at the heart of the company's production strategy. Founded in 1897, BRUKS has achieved a leading position worldwide in wood processing segments such as wood-based panels and sawmills with its constant innovation. Particular attention is paid to machines and complete lines for the processing of waste wood and wood fibers, manufactured on the basis of advanced technologies. Drum chippers, hammer mills, chippers, transport and sorting equipment and butt end rounding machines, all of these equipment manufactured by BRUKS are distinguished both by their high quality and the unique wide range of machines and lines for the needs of sawmills and wood-based panels.

BRUKS works in the following areas:

- Shredding and sorting

- Conveyor systems

- Mobile chippers

- Loading of ships with bulk materials

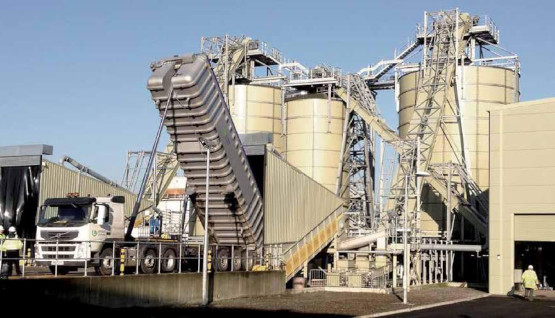

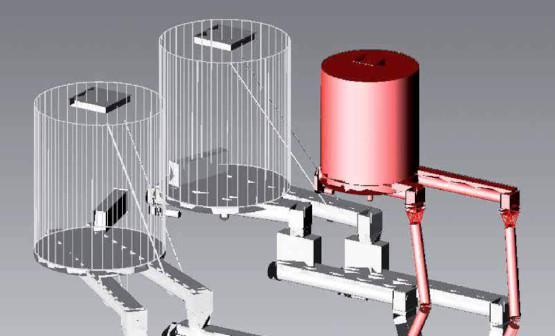

- Warehousing

- Stations for the reception of bulk cargo from heavy vehicles

Among the BRUKS products used in the woodworking industry, the following equipment stands out:

- For shredding and sorting

A wide range of manufactured chippers allows them to be used in almost all segments of the woodworking industry. From automatic lines for the production of heat and electricity to the removal and further processing of waste in the sawmill industry or competent preparation of high-quality technological chips in the pulp and paper industry - chippers of various types produced by BRUKS can also be used in other sectors of the woodworking industry. Wood pulp sorting machines guarantee the corresponding high quality of the resulting wood products for various applications. Machines for removing the butt thickening of logs and trunks The bruks produced by BRUKS, while removing the root thickening of tree trunks, retain the natural conical shape of the tree and significantly increase not only the quality and quantity of processed wood, leading to increased productivity and economic efficiency of production, but also provide the necessary degree of safety in sawmills.

- Disc chippers

Disc chippers with horizontal or gravity loading of the material have revolutionized the production of high quality technological wood chips, which are made in full and strict accordance both with the wishes of customers and with the aim of achieving high productivity and economic efficiency in their application.

- Drum chippers

The extensive product line of drum chippers from BRUKS is one of a kind and is well known throughout the world for its high degree of quality and operational reliability. Drum chippers with horizontal or vertical loading of shredded material allow our customers, through the progressive technologies used in them, not only to simult aneously use a wide range of wood materials at the feed to the machine, but at the same time achieve the required productivity and quality of wood chips at the exit.

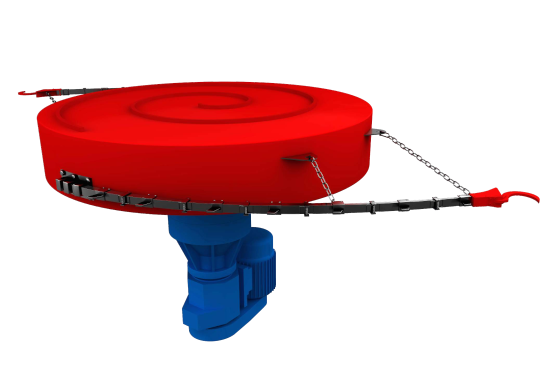

- ROTOM shredders

Regardless of the desired horizontal or vertical loading of the material to be shredded, BRUKS manufactures special shredders with a modular design of the ROTOM type. They make it possible to grind problematic and with the presence of various kinds of impurities wood waste, especially bark and stale wood for its further use as biofuel. Depending on the wood material supplied for grinding and the achievement of the optimally required result, the modular components of such a machine make it possible to produce more than 100 modifications of such a machine.